OUR PROJECTS

Real-world projects, delivered on site.

Every project delivered by Solution Instrumentation responds to a specific industrial reality: operating constraints, performance requirements, compliance standards, and operational continuity.

Here, we present a selection of our projects that illustrate our expertise in instrumentation, automation, weighing, and industrial system integration.

Each installation is designed, built, and commissioned with a single objective: to deliver a reliable, durable solution that is fully integrated into the client’s operating environment.

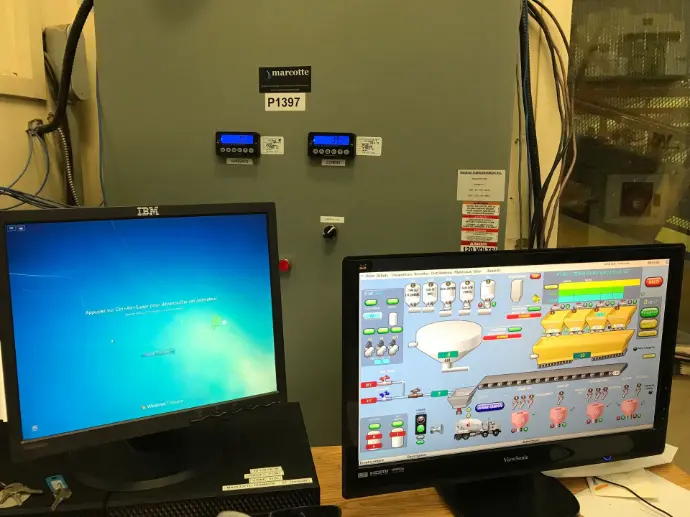

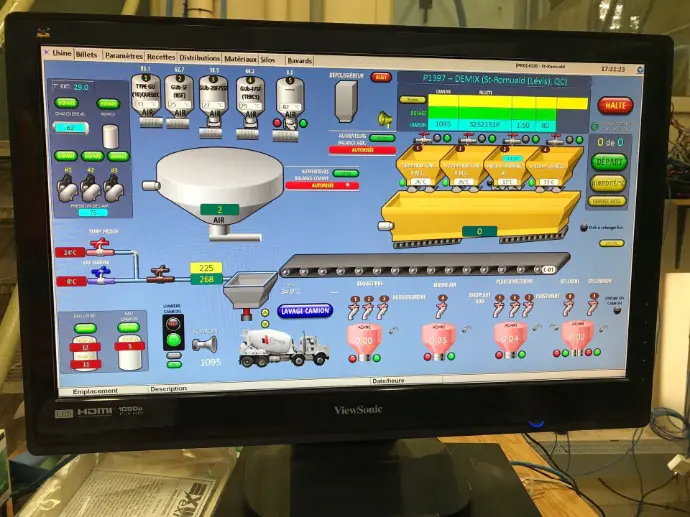

Project – Automated Concrete Batch Plant

Ready-mix concrete production

Context

Modernization of an existing plant under continuous production constraints.

Scope of work

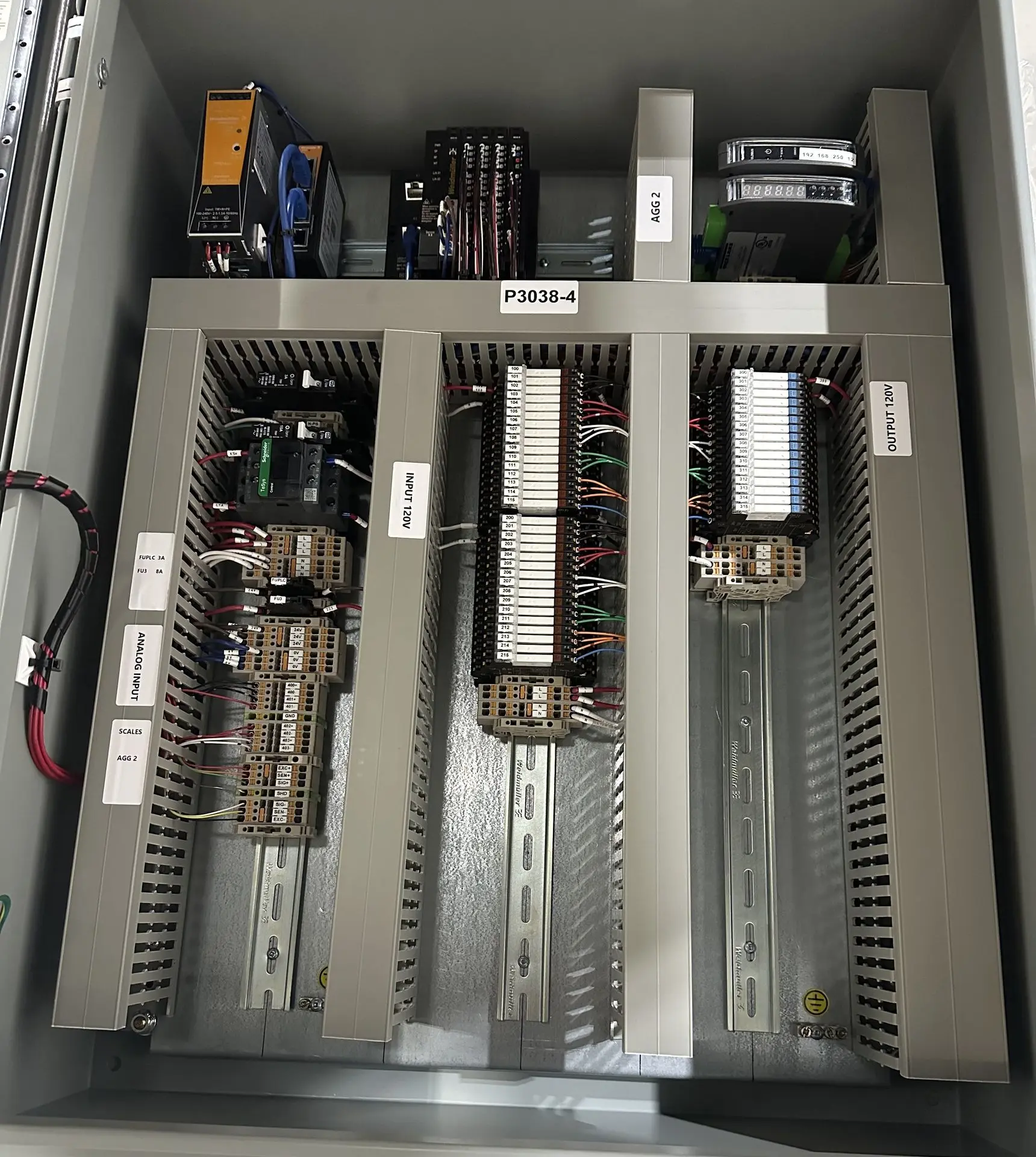

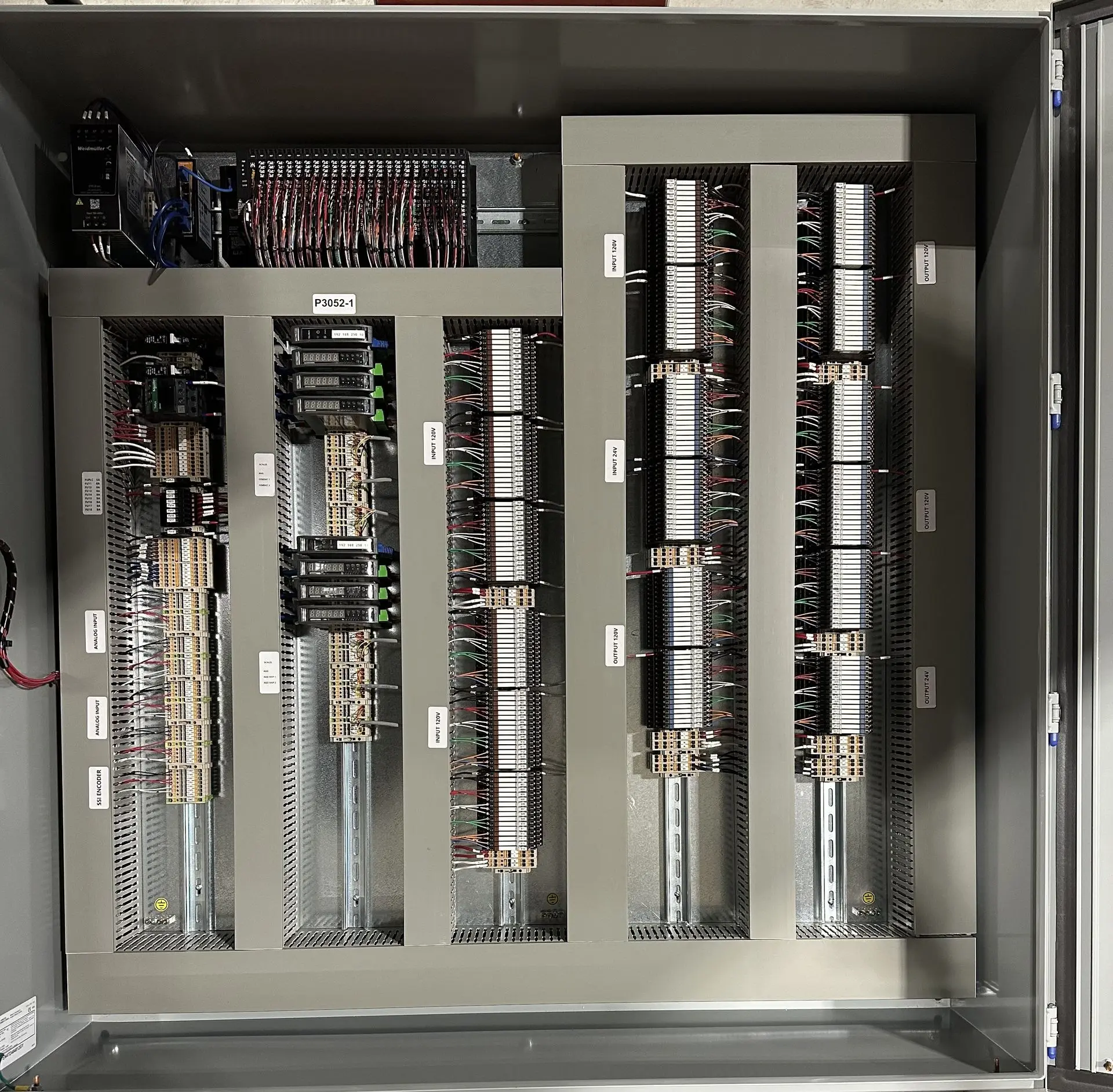

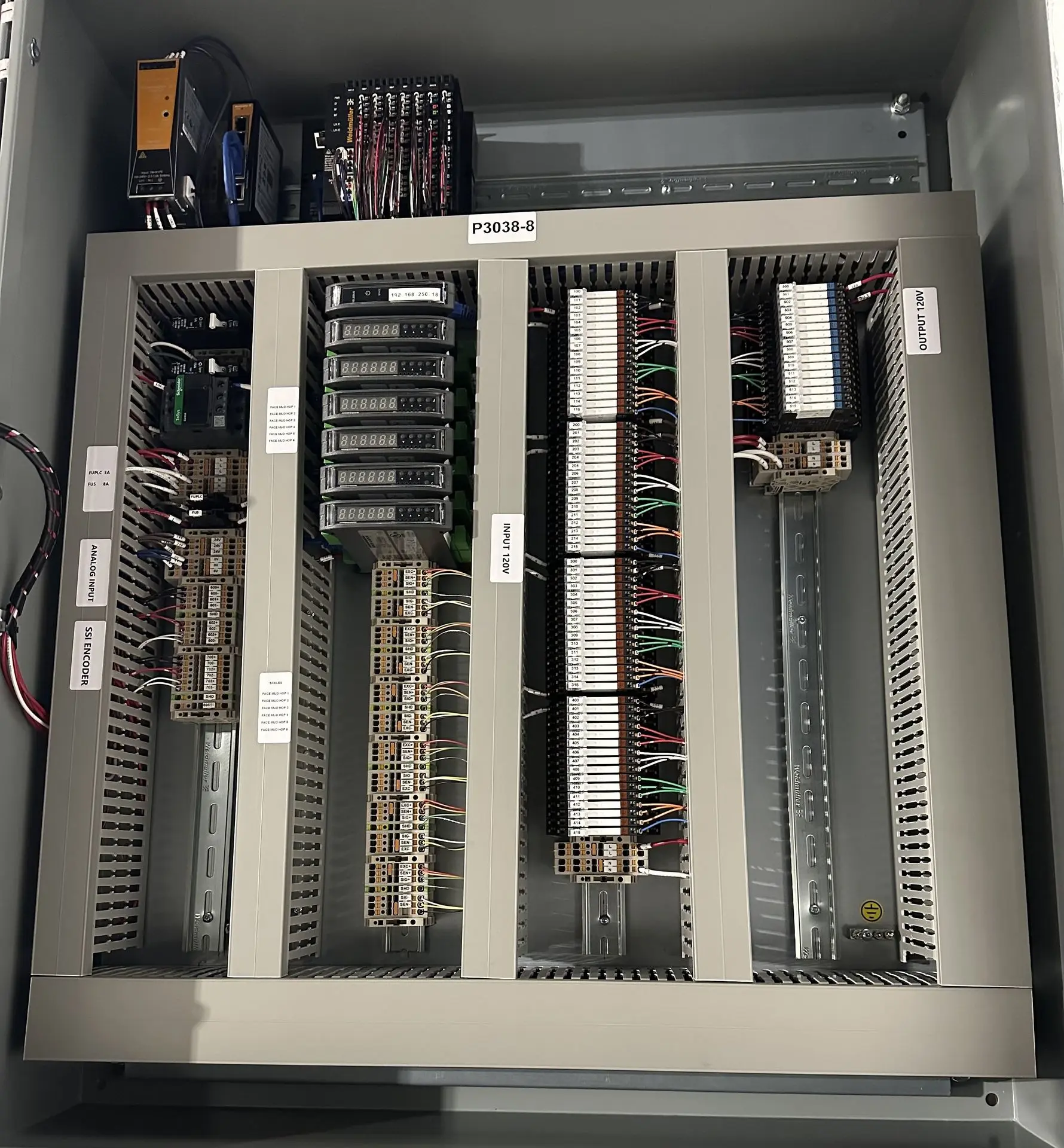

- Fabrication of UL-certified control panels

- Instrumentation and weighing system integration

- On-site calibration and commissioning

Result

Improved batching stability and reduced unplanned downtime. Below are before-and-after photos.

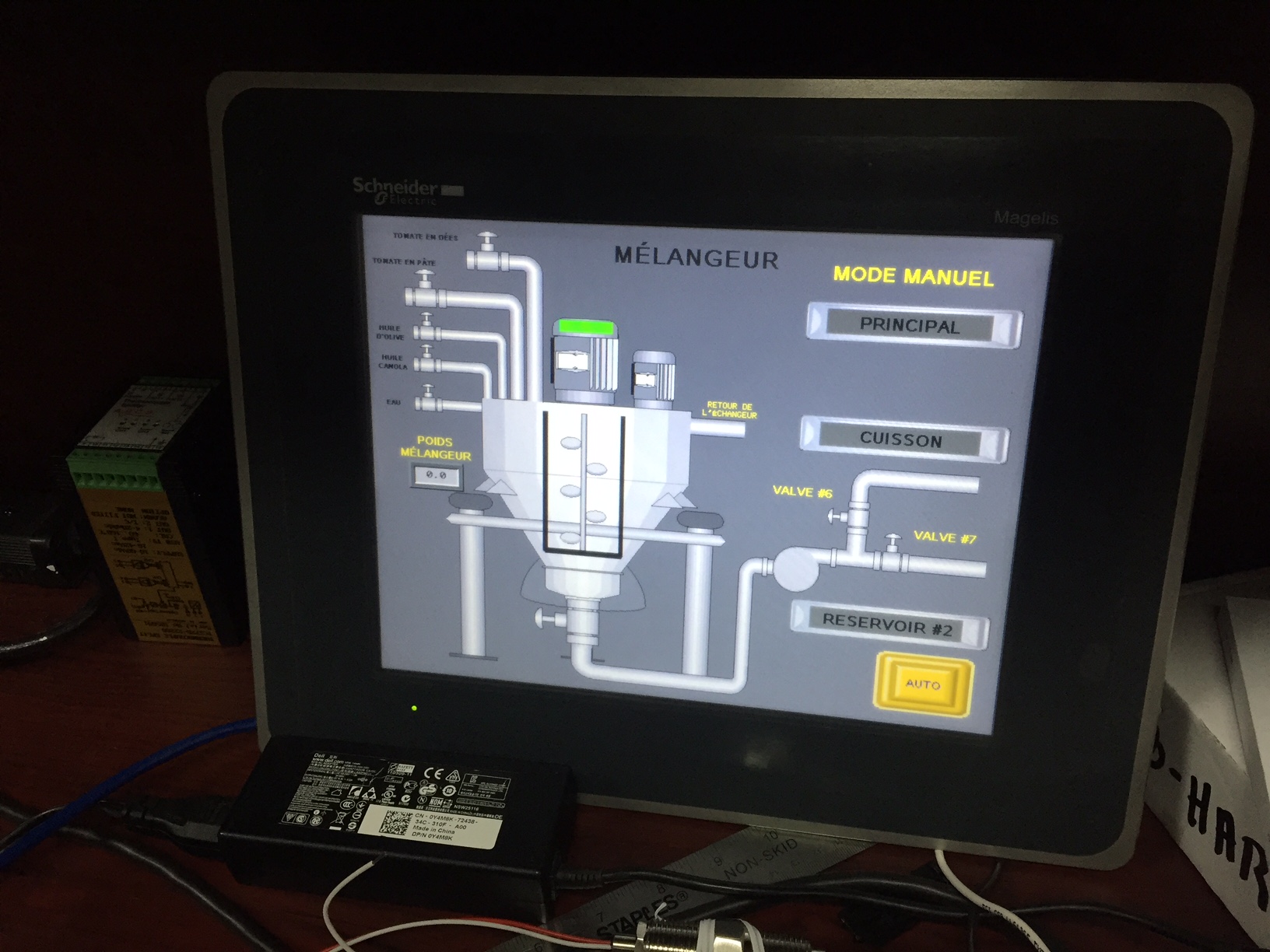

Project – Pizza Sauce Production System

This installation was designed for an industrial kitchen and food processing environment, where hygiene, reliability, and compliance are critical.

Scope of work

• Complete supply of instrumentation and control systems

• UL / cUL certified stainless steel control panels

• 100 percent stainless steel process components

• Food-grade design adapted for washdown environments and continuous production

Project - Admixture System on Load Cells

Instrumentation and integration of an admixture dosing system for a concrete batch plant, including weighing, calibration, and on-site commissioning to ensure precise and reliable process control.

Expertise visible in every detail

The photos presented show real projects executed by our teams in active production environments..

They demonstrate:

- High-quality assembly and wiring

- Compliance with UL and BNQ standards

- Consistency between design, fabrication, and field installation

A project-driven approach

Behind every project are:

- A thorough technical analysis of the process

- Equipment selection adapted to real operating conditions

- Full integration between hardware, control systems, and existing infrastructure

- On-site commissioning, testing and validation

Our projects include both new installations and modernization efforts in environments where precision and availability are critical.

A project-driven approach

Behind every project are:

- A thorough technical analysis of the process

- Equipment selection adapted to real operating conditions

- Full integration between hardware, control systems, and existing infrastructure

- On-site commissioning, testing and validation

Our projects include both new installations and modernization efforts in environments where precision and availability are critical.

Projects aligned with your reality

Our work spans a wide range of industrial contexts, including:

- Modernization of existing facilities without production shutdowns

- New integrated dosing and weighing systems

- Food-grade, abrasive, or high-demand operating environments

- Projects requiring UL, CSA, and BNQ compliance

If your process involves real-world operational constraints, there is a strong chance we have already delivered a solution to a similar challenge.